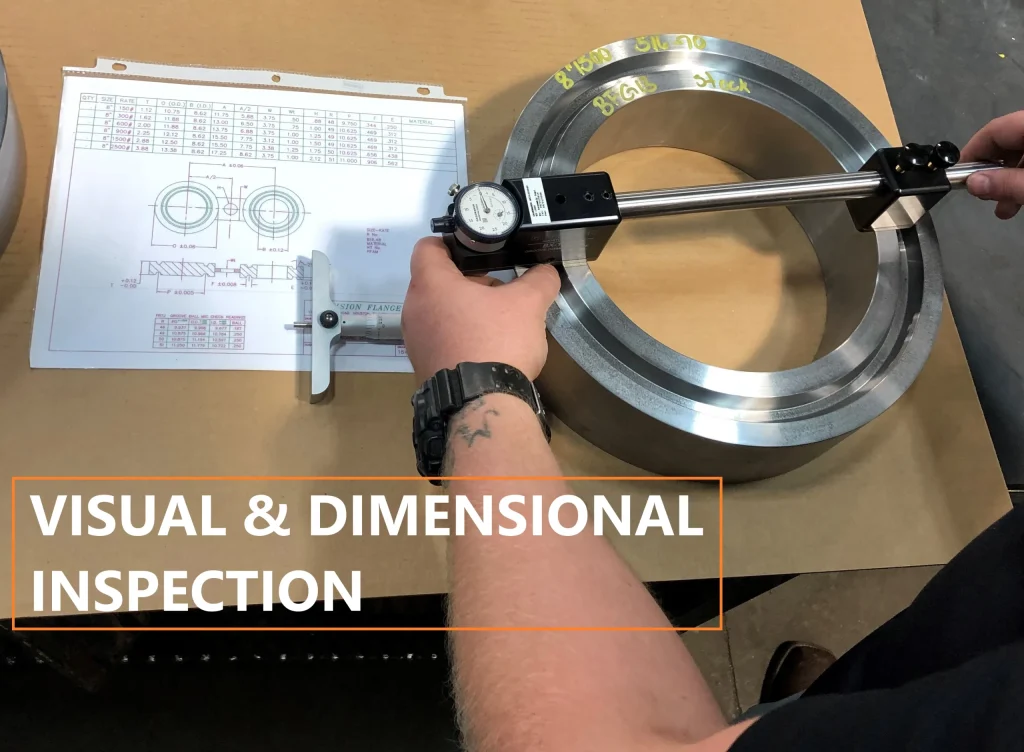

At Precision Flange and Machine, quality is the foundation of everything we do. We are proud to deliver precision-manufactured products that consistently meet and exceed industry standards. Our robust Quality Management System is integrated into every step of production—from meticulous material selection, receiving inspection, quality control on the machining processes, to rigorous final inspection.

Leveraging cutting-edge technology and the expertise of our dedicated team, we ensure every flange and component is crafted for accuracy, reliability, and durability. Beyond manufacturing, we work closely with clients to understand their unique needs, offering tailored solutions and maintaining clear communication throughout the project lifecycle. This client-focused approach enables us to deliver products that not only perform flawlessly but also earn the enduring trust of our customers, project after project.

Our Quality Management System is certified to the stringent ISO 9001:2015 standard, ensuring full compliance and continual improvement in our processes.

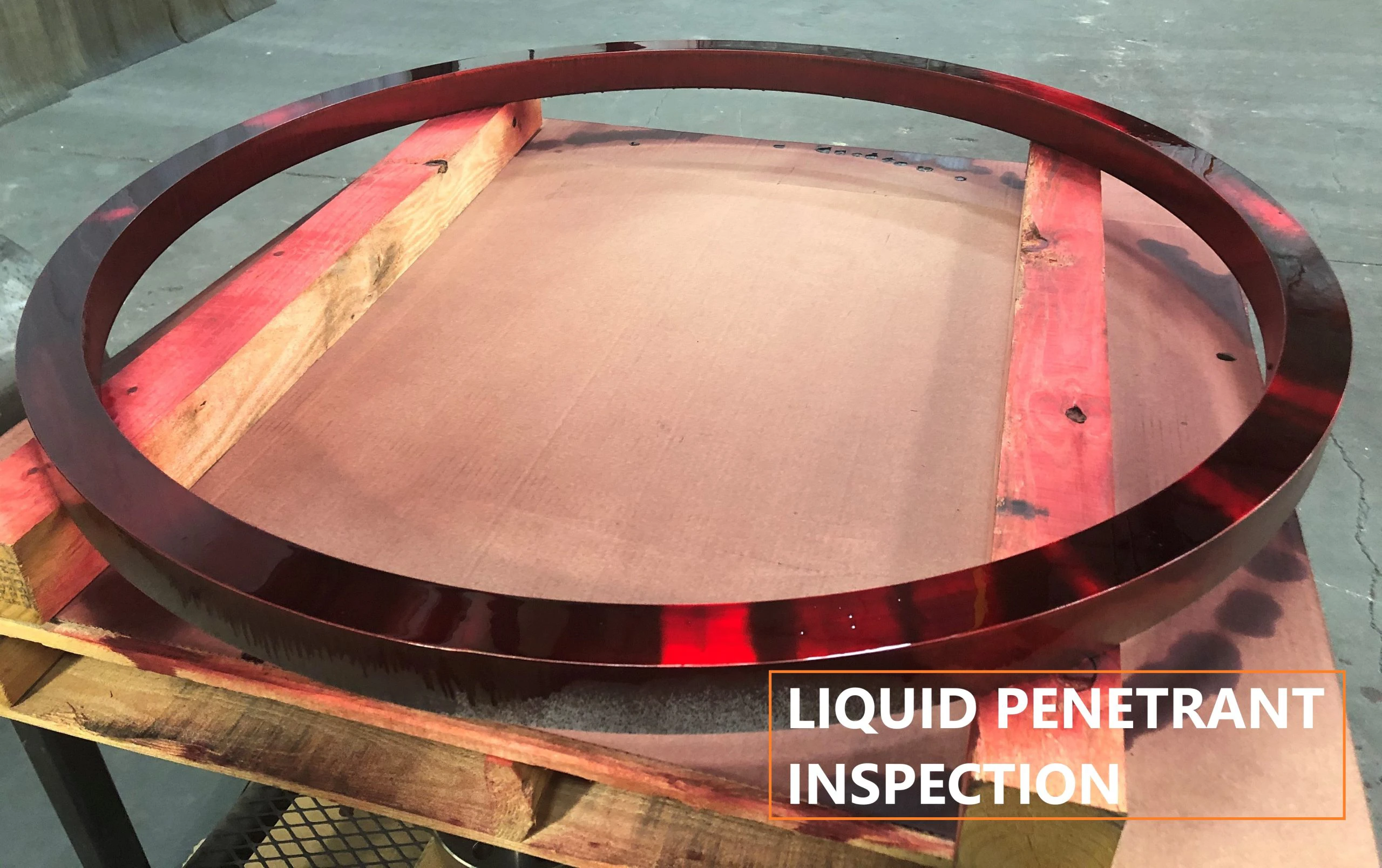

We offer a comprehensive range of Non-Destructive Testing (NDT) services to verify the integrity and quality of our products, including:

At Precision Flange and Machine, we are driven by a relentless pursuit of quality and innovation. Our advanced processes, skilled team, full time ASNT Level III Certified Management, and unwavering commitment to excellence empower us to deliver industry-leading solutions for every project.